Nimisha Vinod

MSc in Food Innovation, MSc in Biotechnology

Traditional meat preservation techniques such as

- salting and curing

- drying

- smoking

were a cornerstone of human survival, all aiming to inhibit microbial growth and spoilage.

With the introduction of refrigeration, new technologies started being developed to maintain the freshness and nutritional value of meat while extending its shelf life.

We talk more about these new technologies in more detail in this article.

Pre-modern methods of meat preservation

Preserving the meat at lower temperatures dates back to the 19th century, as it was the best method to increase the shelf life of the meat.

The traditional methods of meat preservation include freezing the meat at low temperatures to increase its shelf life and quality through the chilling and freezing method.

As moisture in meat was a concern for its spoilage, different salts like

- sodium chloride

- nitrates

were used to preserve meat through salting and curing.

Removing moisture from meat by drying it in sunlight was common, which also helped to improve meat storage. Smoking the meat was considered as an antimicrobial preservation technique which increased meat shelf life and taste.

Conventional meat preservation practices were predominantly based on environmental conditions, availability of chemicals or additives.

A few of these techniques are still practiced today with advanced technology, thereby improving the quality of the meat.

Chilling and Freezing

Meats were stored for longer days and could be transported between places with this technique.[1]

Freezing meat at a lower temperature like –55°C can effectively reduce

- ice recrystallisation

- enzymic reactions

- oxidative rancidity

thus decreasing the meat deterioration.

Another freezing technique called the super-chilling method is where the temperature is reduced from 1 to –2°C for initial surface freezing.

Super-chilling was introduced by Le Danois in 1920 to describe the water being converted to ice in meat by reducing the temperature. This process is most effective in seafood.[2]

This method is cost effective and maintains the frozen condition of the meat even in case of disturbances in cold chains.[3]

Salting and Curing

Other than storing and preserving the meats at low temperatures, adding salts like Sodium chloride or salts of other chemicals were also prominent during early human civilization.

Sodium chloride, which is used extensively in meat preservation, reduces the water content in meat, hence reduces the microbial activity and plays an important role in restructuring the linking protein for meat muscles.[4]

This process of meat processing and preservation dates back to 3000 BC. Adding salts to the meats were important because the process reduced the moisture content in meat.

Moisture is the primary reason for microbial growth and meat spoilage

Curing is also considered as one of the processing techniques for meat preservation.

Both dry cures and pickle or brine cures were used and are still used in food industries. Predominantly, nitrate and nitrite salts are preferred for curing meats, as they give meat a darker colour and flavour, which is liked by consumers and these chemicals prevent oxidation and rancidity in cured meat.

Nitrite, especially, is effective against foodborne pathogenic bacteria C. botulinum spores.[5]

Smoking

Thousands of years ago smoking was a processing and preservation technique. Smoking improves the taste, colour, and palatability of the meat. This method was commonly used, as it helps preserve the meat without spoilage.

Previously, smoking was done using woods from oak, hickory, apple, cherry, and mesquite. The smoke from the wood was reported to produce over 200 various chemical compounds like

- phenols

- acids

- alcohols

- carbonyl compounds

that imparted colour, flavour in meat.

Recent advancements in the smoking process for the processing and preservation of meats is using the smokehouse or thermal processing unit, where the heat is applied using machines and the smoke is controlled.[5]

Meats are smoked at 20–25°C at a relative humidity of 70–80% for cold and at 75–80°C for hot smoking. Smoke is effective against

- Staphylococcus aureus

- Escherichia coli

- Listeria monocytogenes

- Salmonella spp.

which are pathogenic food-borne bacteria. Smoking improves the taste and helps preserve the meat without spoilage.

Drying

Drying the meat to remove the moisture in it thereby extends the meat’s shelf life and has been a processing and preservation method since long ago.

Drying was mostly done using the natural conditions. With the industrial revolution, drying has been more effective with the use of modern techniques using climate chambers.[1]

Modern methods of meat processing

With the advancements in technology, the modern preservation processes increasingly utilize non-thermal (no-heat). These methods are studied to be more effective against microorganisms responsible for food spoilage.

In contrast, pre-modern preservation methods relied on high heat (e.g., smoking and drying) or extreme cold (e.g., freezing), which often compromised the freshness, tenderness, and bioavailability of essential nutrients in meat.

Today’s consumers demand preservation techniques that maintain the freshness and nutritional value of meat while extending its shelf life. All the modern methods like

- high pressure processing

- irradiation

- sonication

- pulsating electric field

- cold plasma

- 3D printing

are designed for minimizing nutrient loss, therefore retaining the freshness and texture along with extended shelf life. These processes are efficient, energy saving and environmentally friendly.

Irradiation

Ionizing irradiation from Gamma rays are effective against harmful food spoiling microorganisms and this method promotes extended meat storage quality.

Spices, fruits, crops and vegetables, fish, seafoods, beef and poultry can be preserved for longer days with this technique.

Gamma rays also help in stabilizing the protein solubility when compared to other radiations.[6]

This technique is very effective against the spore forming foodborne bacteria like Bacillus mycoides, Bacillus weihenstephanensis and Psychrobacillus psychrodurans.[7]

High Pressure Processing (HPP)

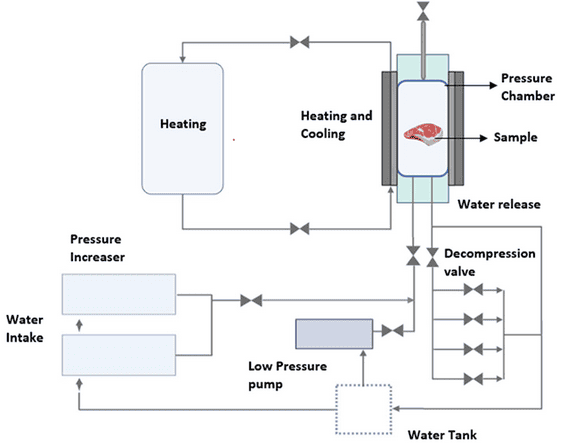

This processing technique, in short HPP, is widely used in recent days. This technique uses a pressure chamber at 100-600 MPa, with water at room temperature.

Meat processing on an industrial scale uses 800 MPa and below pressure, whereas for meat preservation 400–600 MPa is used for 3 to 7 min.[8]

This technique preserves the nutritional quality of the meat by effectively decreasing the food spoiling microbes.

This method works on the principle of isostatic pressure, meaning high pressure is applied uniformly to the meat, effectively inactivating food-spoiling microorganisms. Compared to traditional methods, this technique better retains the essential nutrients in meat.

In HPP, meat is placed inside the pressure chamber of the machine, which is then filled with water. The pressure is increased, typically up to 600 MPa, for 3 to 7 minutes. Under these conditions, harmful pathogens are inactivated while the nutritional and sensory qualities of the meat are preserved.

The advantage of isostatic pressure is that the product regains its structure after the process.[9]

After processing, the pressure is released, the water is drained, and the meat is ready for packaging. This process extends the shelf life of the meat. HPP also helps retain the freshness, texture, and overall quality of meat. Additionally, it can restructure meat proteins, improving their bioavailability for human digestion.[10]

HPP is often used to minimise Listeria monocytogenes

HPP is often used in the control of the major food spoiling bacteria Listeria monocytogenes, especially in ready-to-eat products, as a post packaging processing step.

This method is also considered as safe to the environment and an effective method for processing and preserving meats.

Sonication

Sonication or ultrasound is gaining popularity as an innovative technique in food processing. Sonication prevents the food spoilage and growth of foodborne microbes without impacting the nutritional value and quality of the meat.

Ultrasound waves of high power and low frequency of 20 kHz – 100 kHz pass through the food causing physical and biochemical changes in food.

This process thus reduces the use of chemical additives or preservatives, is cost effective and environmental friendly.

Pulsating Electric Field (PEF)

PEF uses high electric short pulses from 10 to 50 KV/cm to produce electric charges across food.

These electric pulses inactivate the food spoiling microbes while keeping the nutritional value and quality of the meat intact.

Applying a pulsating magnetic field to process the food through another technique called oscillatory magnetic field uses the same application as PEF.[8]

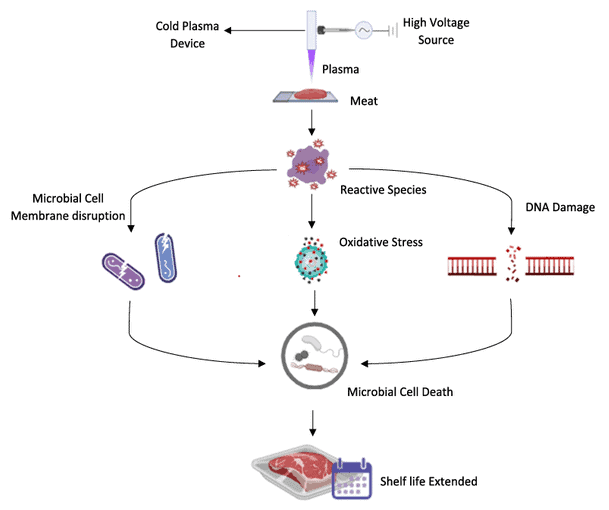

Cold Plasma (CP)

CP uses ionized charges to kill the food spoiling microbes, which creates an antimicrobial effect on meat products.[10]

Ionizing gases like

- air

- oxygen

- nitrogen

- argon

are used as inactivating agents. Cold plasma is effective against a wide range of microbes and retains the nutritional value and quality of the food.[10]

3D Printing

This technique is a novel method in which food is printed in specific shapes using a 3D printer.

When printing meats, layers or gellable proteins or hydrocolloids are added for texture to get the meat form.

The novel technology is gradually gaining its attention due to its waste reduction, consumer preference in ingredients and new food innovations and less energy consumption.

Combination of Technology

Specific microorganisms or their disease-causing spores can develop resistance and thrive in extreme processing conditions, eventually growing antibiotic resistance. These microbes cause severe or even fatal foodborne illness.

For example, Staphylococcus aureus, a popular foodborne bacterium, can survive even in cooked meat.[11,12]

Natural preservatives like plant extracts have known health benefits and antimicrobial properties, but they are often not very effective on their own.

Combination technology combines modern techniques of food processing like HPP with natural preservatives to increase their effectiveness. This approach helps keep the meat safe from microbes while maintaining its texture, flavour, and appearance. In addition, it offers a healthier way to preserve meat.

The studies, below, have reported significant reduction in foodborne microbes without altering the quality of food while being environmentally friendly by avoiding the use of preservatives and additives.[13]

γ-irradiation in combination with the antimicrobial agents like Sodium nitrate and Nisin, also with antioxidants like Butylated Hydroxytoluene and rosemary extract on mutton meat emulsions were studied for their synergistic effect. Rosemary extracts are known for their flavour enhancement and are a great natural antioxidant.

RELATED — Rosemary (Salvia rosmarinus)

The study also reported that the combination of nisin, a natural antimicrobial peptide, and irradiation was as effective as using Sodium nitrate, a traditional antimicrobial agent, and irradiation.

This suggests that modern preservation techniques, such as γ-irradiation, can enhance the effectiveness of natural additives, potentially reducing the need for conventional chemical preservatives.[14]

Cold plasma with lemongrass essential oil on pork loin. A study revealed that lemongrass essential oil when combined with cold plasma reported a significant decrease in the growth of Listeria monocytogenes, a common and harmful foodborne bacterium. This combination did not alter the meat flavour, texture, thus preserving their quality.[15]

RELATED — Lemongrass (Cymbopogon citratus)

HPP with sage powder on beef burgers. HPP is an effective modern preservation method. Sage is a herbal plant used in flavour enhancement and meat preservation. The plant contains phenolic compounds that act as an antioxidant.

Sage is used in flavour enhancement and meat preservation

The chances that the meat can get oxidized during storage are high. According to a study, the combination of HPP with sage powder on beef burgers ceased the natural oxidation process through 60 days of the chilled meat storage. This method was also effective against microbial infection during storage.[16]

HPP with thymol on sliced-dry cured ham. HPP at 450 MPa for 10 minutes when combined with thymol suppressed Listeria monocytogenes growth, in sliced dry-cured ham, with no added antimicrobial agents to meat product. Thymol is one among the major constituents of thyme essential oil exhibiting antibacterial properties.[17]

HPP with lemon balm or Melissa officinalis extracts and chemical constituents on raw ground beef. HPP along with extracts of Melissa officinalis and chemical constituents at 0.5 and 1% concentrations with pressure at 350 and 400MPa for 15 minutes controlled the growth of Escherichia coli in raw ground beef.[18]

References

(1) Vasilev, D., Stajkovic, S., Karabasil, N., Dimitrijevic, M., & Teodorovic, V. (2019). Perspectives in meat processing. IOP Conference Series Earth and Environmental Science, 333(1), 012024.

(2) Zhou, G., Xu, X., & Liu, Y. (2010). Preservation technologies for fresh meat – A review. Meat Science, 86(1), 119–128.

(3) Rahman, U. U., Sahar, A., Ishaq, A., Aadil, R. M., Zahoor, T., & Ahmad, M. H. (2018). Advanced meat preservation methods: A mini review. Journal of Food Safety, 38(4).

(4) Gómez, I., Janardhanan, R., Ibañez, F. C., & Beriain, M. J. (2020). The effects of processing and preservation technologies on meat quality: sensory and nutritional aspects. Foods, 9(10), 1416. https://doi.org/10.3390/foods9101416

(5) Lonergan, S. M., Topel, D. G., & Marple, D. N. (2019). Fresh and cured meat processing and preservation. The Science of Animal Growth and Meat Technology. Chapter 13.

(6) Kim, T., Hwang, K., Ham, Y., Kim, H., Paik, H., Kim, Y., & Choi, Y. (2019). Interactions between raw meat irradiated by various kinds of ionizing radiation and transglutaminase treatment in meat emulsion systems. Radiation Physics and Chemistry, 166, 108452. https://doi.org/10.1016/j.radphyschem.2019.108452

(7) Condón-Abanto, S., Pedrós-Garrido, S., Cebrián, G., Raso, J., Condón, S., Lyng, J., & Álvarez, I. (2018). Crab-meat-isolated psychrophilic spore forming bacteria inactivation by electron beam ionizing radiation. Food Microbiology, 76, 374–381.

(8) Rudy, M., Kucharyk, S., Duma-Kocan, P., Stanisławczyk, R., & Gil, M. (2020). Unconventional methods of preserving meat products and their impact on health and the environment. Sustainability, 12(15), 5948. https://doi.org/10.3390/su12155948

(9) Keyata, E., & Bikila, A. (2024). Effect of high-pressure processing on nutritional composition, microbial safety, shelf life and sensory properties of perishable food products: A review. Journal of Agriculture, Food and Natural Resources, 2(1), 69–78.

(10) Ghazali, M. H., Saleem, F., & Bashir, L. (2025). Cold plasma and high-pressure processing in sustainable meat preservation: a review. Food, Nutrition and Health., 2(1). https://doi.org/10.1007/s44403-025-00032-1

(11) Roobab, U., Chacha, J. S., Abida, A., Rashid, S., Muhammad Madni, G., Lorenzo, J. M., Zeng, X. A., & Aadil, R. M. (2022). Emerging trends for nonthermal decontamination of raw and processed meat: Ozonation, high-hydrostatic pressure and cold plasma. Foods, 11(15), 2173. https://doi.org/10.3390/foods11152173

(12) Khalafalla, F. A., Ali, H. M., & El-Fouley, A. (2019). Microbiological evaluation of chicken meat products. Journal of Veterinary Medical Research, 26(2), 151–163.

(13) Kaur, R., Kaur, L., Gupta, T. B., Singh, J., & Bronlund, J. (2022). Multitarget preservation technologies for chemical‐free sustainable meat processing. Journal of Food Science, 87(10), 4312–4328.

(14) Akhter, R., Masoodi, F. A., Wani, T. A., Rather, S. A., & Hussain, P. R. (2021). Synergistic effect of low dose γ-irradiation, natural antimicrobial, and antioxidant agents on quality of meat emulsions. Radiation Physics and Chemistry, 189, 109724.

(15) Cui, H., Wu, J., Li, C., & Lin, L. (2017). Promoting anti-listeria activity of lemongrass oil on pork loin by cold nitrogen plasma assist. Journal of Food Safety, 37(2), e12316.

(16) Mizi, L., Cofrades, S., Bou, R., Pintado, T., López-Caballero, M. E., Zaidi, F., & Jiménez-Colmenero, F. (2019). Antimicrobial and antioxidant effects of combined high pressure processing and sage in beef burgers during prolonged chilled storage. Innovative Food Science & Emerging Technologies, 51,32–40.

(17) Pérez-Baltar, A., Serrano, A., Bravo, D., Montiel, R., & Medina, M. (2018). Combined Effect of High Pressure Processing with Enterocins or Thymol on the Inactivation of Listeria monocytogenes and the Characteristics of Sliced Dry-cured Ham. Food and Bioprocess Technology, 12(2), 288–297.

(18) Chien, S., Sheen, S., Sommers, C., & Sheen, L. (2018). Combination Effect of High-Pressure Processing and Essential Oil (Melissa officinalis Extracts) or Their Constituents for the Inactivation of Escherichia coli in Ground Beef. Food and Bioprocess Technology, 12(3), 359–370.